Accessories

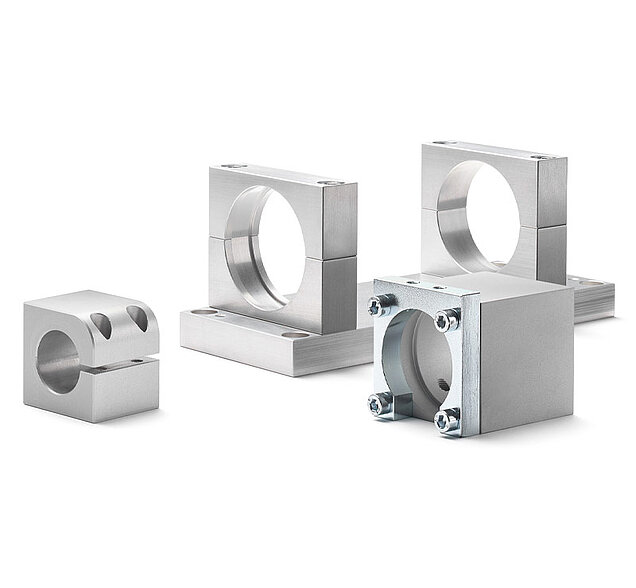

Retainers and clamping shells

Optimal grip, precise working: Our specially designed retainers and clamping shells ensure an optimal grip on the welding unit and thus enable precise working.

Key Features

- Made from anodized aluminum surfaces

- Lightweight, also suitable for robots

- Suitable for horizontal and vertical clamping

- Optimized for EUROSONIC welding and cutting systems

Accessories

Feed unit

The latest production methods for durability and ease of maintenance: The EUROSONIC feed unit was manufactured using the latest production methods. The built-in bearings, shafts and cylinders are components from leading manufacturers and are characterized by ease of maintenance and durability. They are fitted with wipers as standard. Depending on the version of the feed unit, it is possible to use a changing system. The feed unit has a pneumatic drive that uses double-acting cylinders. Optionally available with end position damping or a hydraulic damper. The feed unit is designed for our oscillating units. The size of the feed unit depends on the system frequency. We produce these units with various cylinder diameters and strokes. The initial and operational position can be queried using sensors.

Key Features

- Operating pressure from 1.0 to 8.0 bar

- For system frequencies from 20 kHz to 60 kHz

- Mounting of the feed unit in any position

- Additional retainers for sensors or path measurement systems (optional)

Accessories

Fixtures

Optimally adapted to the application: We produce fixtures that suit your application perfectly. We pay close attention to getting the shape and choice of material right to ensure that parts are optimally secured during the welding process.

Key Features

- Contour creation from 3D data

- Use of high-quality cast resin to protect the welding piece

- Customized binder for an extra-secure fit possible