Good vibrations for strong metal joints

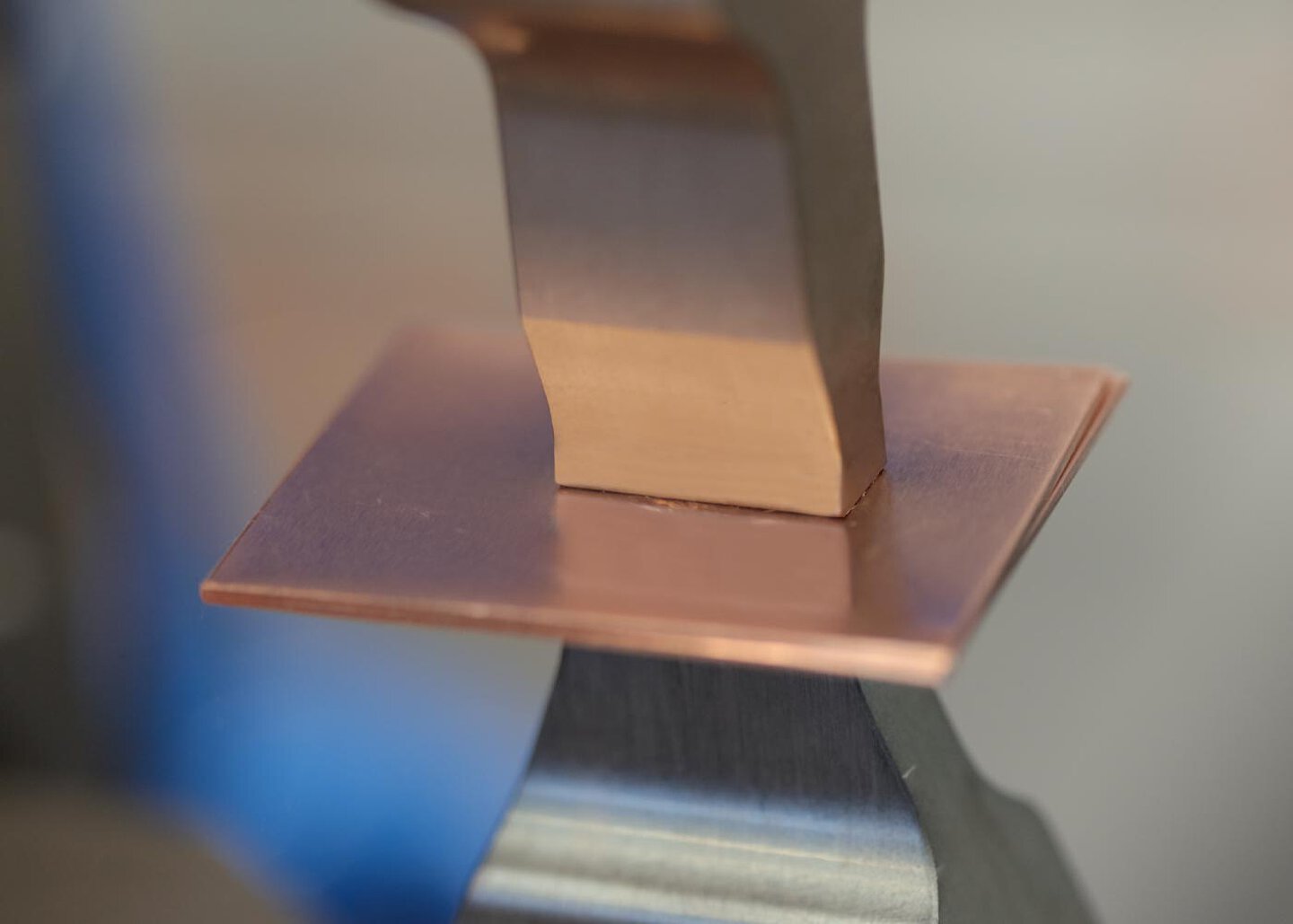

In comparison with conventional welding of metals, ultrasonic welding is faster, more efficient and better for the environment. During this process, metal surfaces are moved against one another by high-frequency oscillations. Pressure and frictional heat cause the surfaces to fuse together and create a high-strength joint. This flexible method is suitable for a whole host of applications.

Advantages of ultrasonic metal welding

- Welding within fractions of a second

- High level of precision

- High strength

- Electrically conductive joints

- No damage to materials caused by heat input

- No smoke or sparks

A world first!

Contact our

team of experts!

Our team of experts is happy to help you find the best solution for your project. Simply fill out the following contact form and a member of our sales team will be in touch.