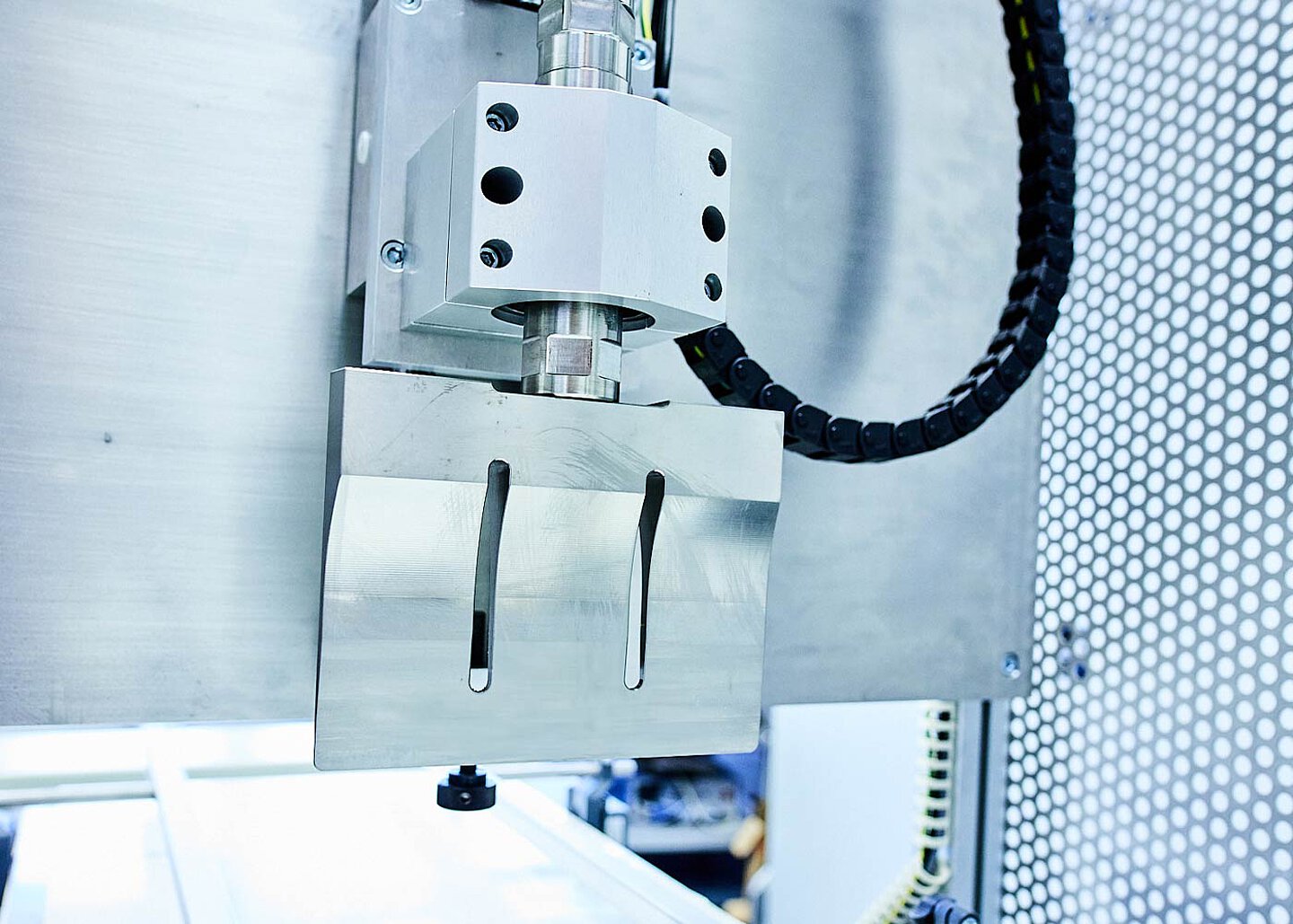

Better cutting with ultrasound

In ultrasonic cutting, the material is made to vibrate with the help of high-frequency oscillations and causing heat up to its melting point. The cut is made with almost no resistance. In comparison to other methods, ultrasonic cutting is especially precise and gentle with no deformation of the material and no residue adhering to the cutting tool. The method is just as suitable for sensitive materials such as food or textiles as it is for particularly tough materials such as rubber.

Advantages of ultrasonic cutting

- No deformation of the material being cut

- Clean cut surfaces and edges

- Minimal heat buildup

- High cutting speed

- High precision

- No product residue adhering to the tool

A world first!

Contact our

team of experts!

Our team of experts is happy to help you find the best solution for your project. Simply fill out the following contact form and a member of our sales team will be in touch.